In many oilfields around the world, especially those located in remote or harsh environments, production conditions are far from ideal. High water cut, sand production, fluctuating flow rates, and low ambient temperatures often coexist, creating significant challenges for oil-gas separation systems.

Under such conditions, separator performance is no longer determined by nameplate capacity alone. Instead, long-term operational stability, adaptability, and maintenance simplicity become the true measures of system quality.

This article discusses key engineering considerations for designing oil-gas separation systems in high water cut and sand-producing fields, based on practical project experience.

1.High Water Cut: When Separation Becomes a Hydraulic Problem

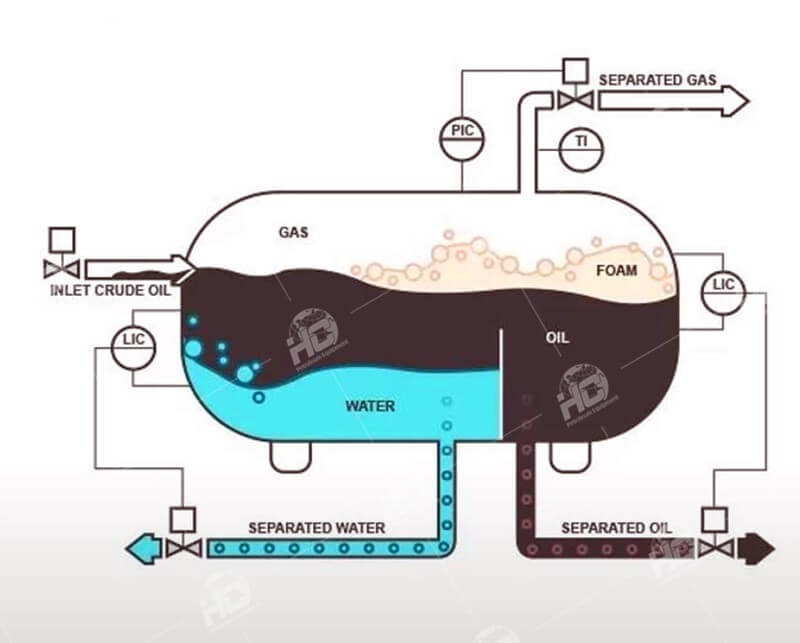

In high water cut production, the separator is effectively handling a large volume of liquid with relatively limited oil content. This changes the nature of separation in several ways:

Liquid residence time becomes critical

Level control stability directly affects separation efficiency

Small disturbances can easily lead to liquid carryover or gas blow-by

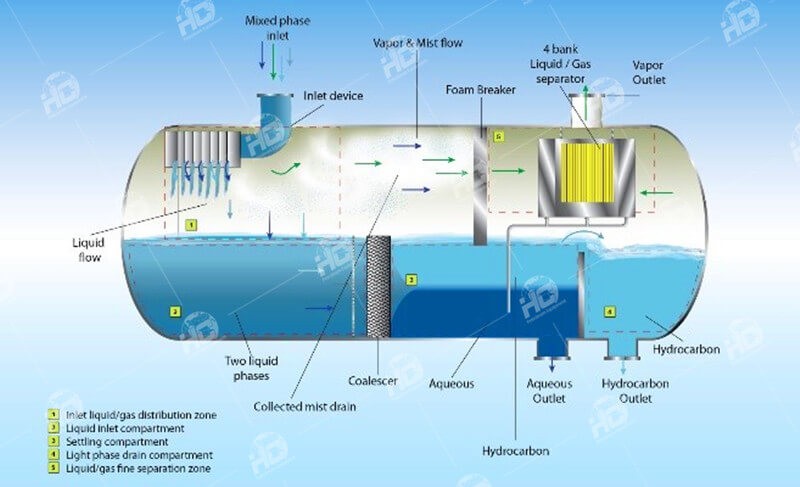

In such cases, oversizing the separator does not necessarily solve the problem. More important is the internal configuration, including inlet device selection, flow distribution, and liquid level control philosophy.

For high water cut conditions, conservative liquid handling design and stable level control strategies are often more valuable than chasing higher nominal throughput.

2.Sand Production: Designing for Erosion and Operability

Sand is one of the most underestimated factors in separator design. While small sand rates may not immediately affect separation efficiency, they can cause long-term operational issues:

Erosion of inlet devices and internals

Blockage of level instruments and drain lines

Increased maintenance frequency and unplanned shutdowns

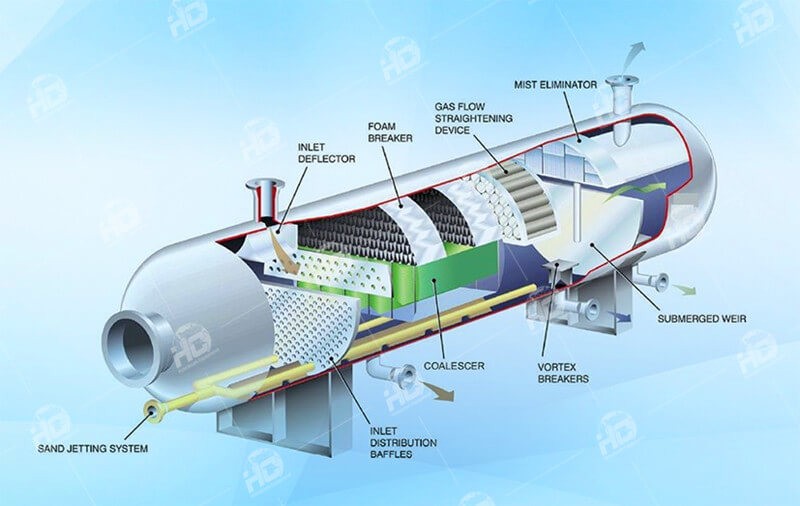

An effective separation system should consider sand handling from the earliest design stage. This includes:

Proper inlet momentum control to reduce erosion

Adequate sand collection and removal capacity

Maintenance-friendly sand drain arrangements

In sand-producing fields, a “separator-only” mindset is insufficient. The system must be designed to manage solids throughout the operating life, not just during initial production.

3.Low Temperature Operation: Stability Over Complexity

Low ambient temperatures introduce additional challenges, particularly during startup, turndown, and intermittent operation. Common issues include:

Increased fluid viscosit.

Instrument reliability degradation

Risk of freezing in drains and control lines

While it is tempting to add complex heating or control schemes, experience shows that simplicity and robustness often lead to better results. Practical solutions may include:

Localized heating for critical sections

Simplified control logic with wider operating margins

Equipment layouts that minimize cold spots

A stable system that performs consistently is usually more valuable than a highly optimized but sensitive design.

4.System-Level Thinking: Beyond the Separator Vessel

In challenging field conditions, separator performance cannot be isolated from the overall production system. Upstream flow instability, downstream backpressure, and operating practices all influence separation results.

Successful projects often share one common approach: system-level design thinking. Instead of optimizing individual equipment in isolation, the entire process—from wellhead to downstream handling—is evaluated as a whole.

This approach helps avoid common pitfalls such as:

Separators forced to compensate for unstable inlet conditions

Overly tight control schemes that amplify disturbances

Mismatch between design assumptions and actual operating behavior.

5.Conclusion: Designing for Reality, Not Ideal Conditions

High water cut and sand-producing fields are not exceptional cases—they are increasingly common as oilfields mature and new developments move into more challenging environments.

Under such conditions, the most effective oil-gas separation systems are those designed with realistic operating scenarios in mind. Robust internals, stable control strategies, sand-tolerant configurations, and system-level integration often matter more than theoretical efficiency.

At HC, we focus on delivering separation solutions that perform reliably under real field conditions, combining engineering judgment with practical design experience to support long-term, stable operation.

-

2025 / 12 / 29

Customized Shell and Tube Heat Exchanger for Syria Project

Customized Shell and Tube Heat Exchanger for Syria Project -

2025 / 11 / 01

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project

HC Successfully Delivers Gas-Liquid-Sand Separator for Xinjiang Oilfield Project -

2025 / 08 / 20

HC Successfully Delivered Filter Coalescer Skid to Malaysia

HC Successfully Delivered Filter Coalescer Skid to Malaysia

- +86 158 6190 3617