Dry Gas Filter

Dry Gas Filters is filtering unit of the gas pipeline or gas processing facility where no liquids (slug) of the flow stream are presented, but solids are presented. It is commonly horizontal vessel with filter cartridges inside. Solid removal efficiency is 100% when size of solids is 10 microns & larger, and 99%, when size of solids are 1-3 microns. In comparison, filter separator can handle also the liquids.

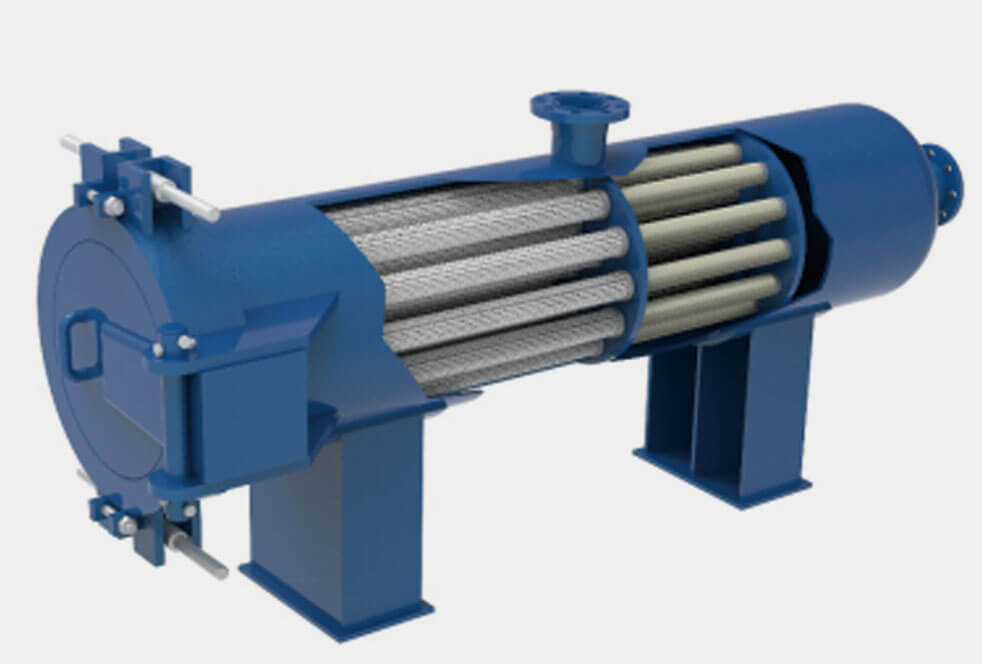

- Typical Horizontal Dry Gas Filter

Design and equipment composition of field treatment and processing facilities, as well as transport pipelines, depend on the type of gas reservoirs. Some fields produce saturated associated gas (gas associated with crude oil), while fields produce a dry gas (free gas). As gas comes out from reservoir through special tubing and pipes, gas flow contains solids after passing removal of mist, which gas to be filtered before gas is supplied to valve and metering units. In this case, dry gas filters are required.