Water Bath Heater, also known as "oilfield heat treat" or "water jacket heater" is an efficient heating treater specifically designed for oilfield extraction and production processes. This product combines thermal oil heating with liquid treatment capabilities, aiming to provide reliable oilfield treatment solutions.

As an efficient and reliable oilfield heating and treating equipment, the heater treater is widely used in oilfield development, petroleum production, and transportation systems. It enhances operational efficiency, reduces energy consumption, and ensures the quality and stable supply of oil and gas.

Process Principle and Operation of Water Bath Heater

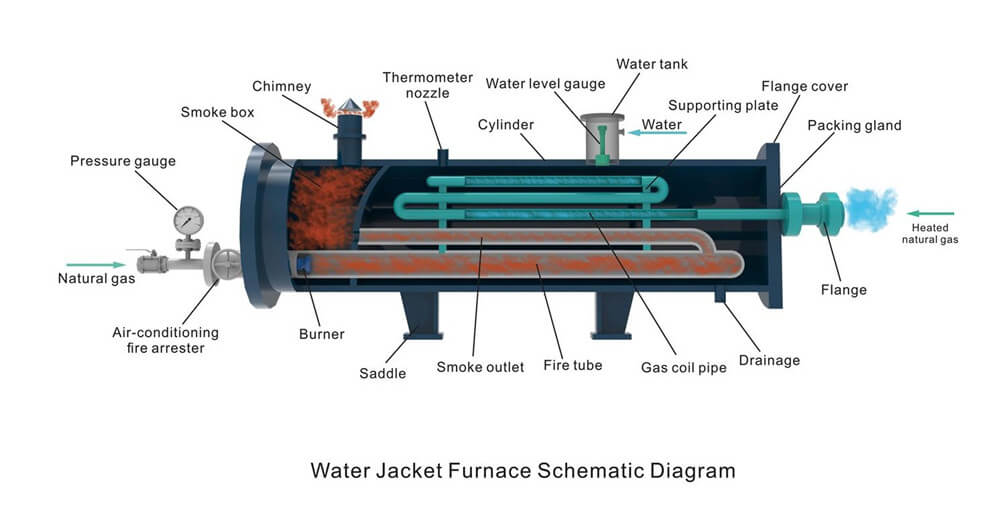

A water bath heater is an indirect heating device widely used in the oil and gas industry for heating and pressure regulation of natural gas, crude oil, and other fluids. Its working principle is to generate heat through a combustion system, transfer the heat into water or thermal fluid as the medium, and then indirectly heat the process fluid flowing inside the coils. This design prevents direct flame contact, ensuring safety and reliability.

Process Principle:

The heater body is typically composed of three main parts: the combustion chamber, the heat exchange coil, and the water bath. When the burner ignites, fuel (natural gas or diesel) is burned in the chamber, and the released heat raises the temperature of the surrounding water or thermal liquid. The process fluid flows through the coil immersed in the heated bath, where heat is transferred through conduction and convection.

Operation Workflow:

- Combustion Heating – The burner ignites, and the flame in the combustion chamber transfers heat to the surrounding bath liquid.

- Heat Transfer – The heated water or thermal fluid forms a stable temperature field around the coils.

- Fluid Heating – Natural gas or crude oil enters the inlet of the coil and is gradually heated as it flows through the coil.

- Outlet Delivery – Once the fluid reaches the desired temperature, it exits through the outlet for further processing, transportation, or pressure regulation.

- Automatic Control – Temperature controllers and safety devices ensure stable heating while preventing overheating or low water level operation.

The water bath heater features uniform heating, safe operation, and a high level of automation , making it a reliable choice for gas pressure regulating stations, gathering stations, and oilfield heating applications.

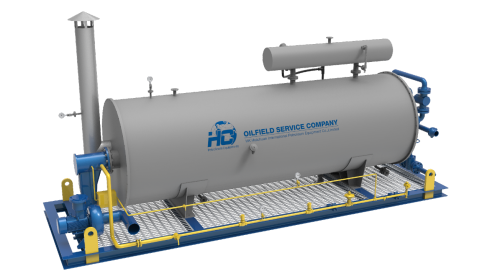

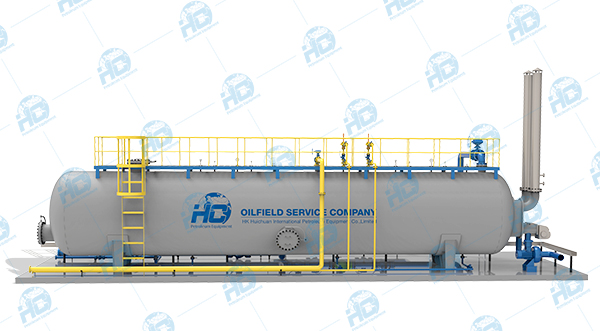

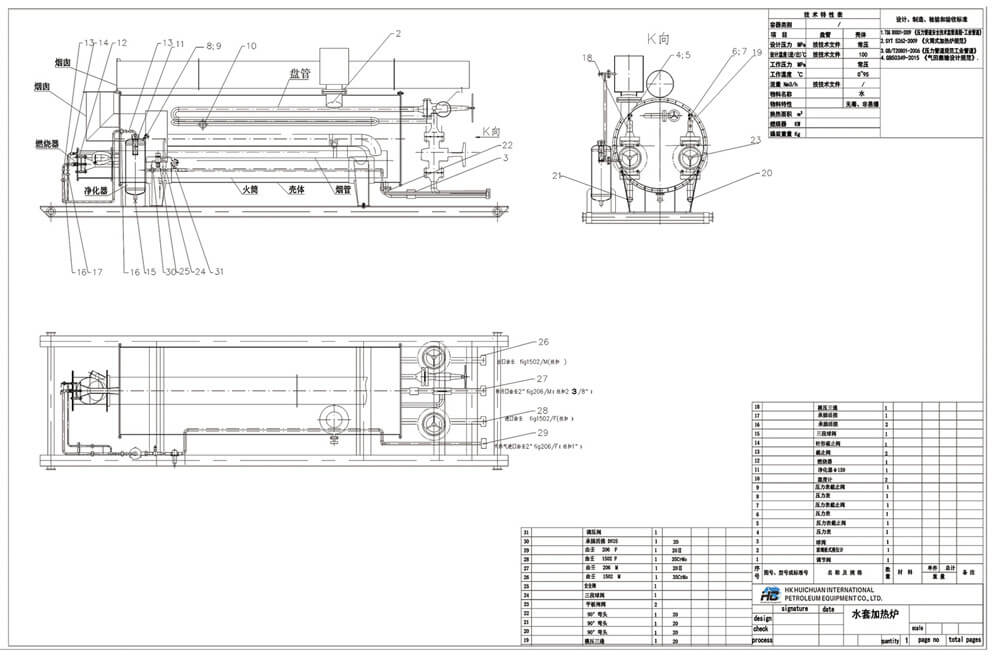

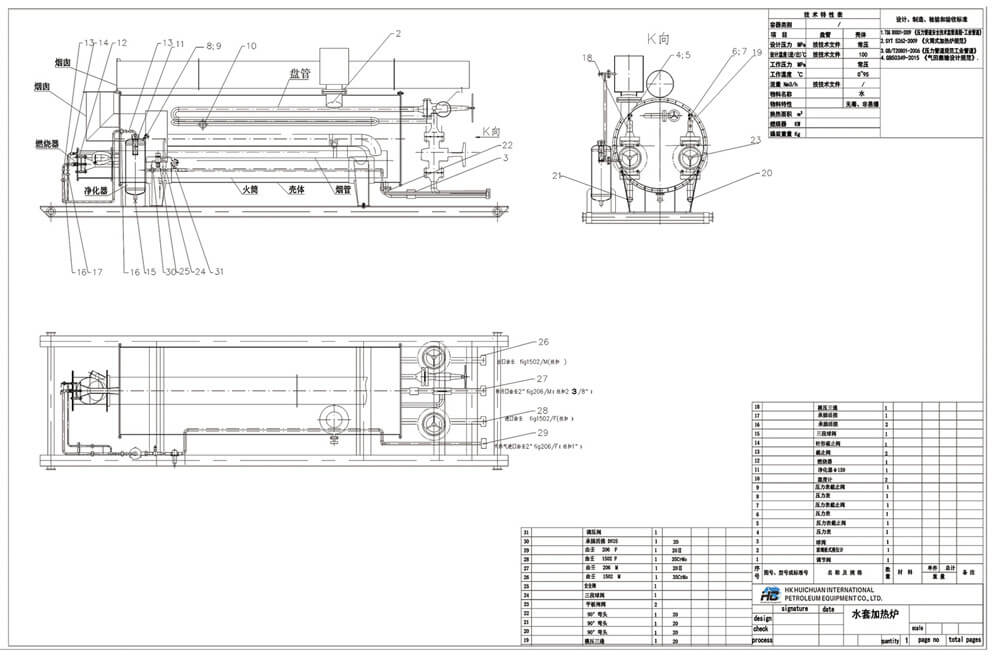

Water Bath Heater

The configuration of the heater may differ depending on the process application. Usually, the heater consists of main body with coil tubes, burner, firetube and flue stack. Sometimes skid may consider an expansion tank.

The main body refers to the basic vessel into which the firetubes and process coils are inserted from opposite ends. The burner ignites the fuel gas or fuel oil and blow it into firetube to heat the water in the vessel, and the hot water heats the medium in the coils such as crude oil or raw natural gas. The process coils are “bathing” in the water, and that’s why it’s called a water bath heater.

The heater shell has two saddle types supports, which is cuboid form and mounted on skid or special-designed bases. Outlet temperature may vary, but usually don’t exceed 86-88 °C.

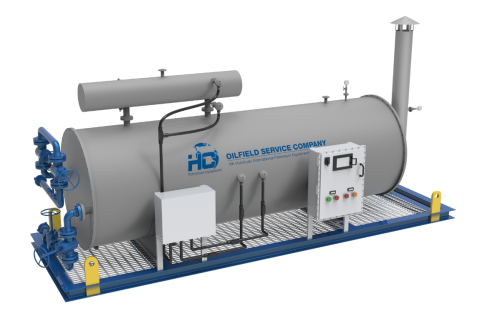

Burner Management System

HC also offers water bath heaters with several types of Burner Management System (BMS). BMS is widely use in industrial heaters, boilers, and furnaces. BMS is designed to perform several functions, such as protection, operation, control, monitor, and communication. BMS controls and monitors pilot lines, fuel gas lines, temperature, pressure of whole unit, as well as shutdowns and alarms in case of emergency. BMS is very essential for oil & gas heaters. However, there are several types of BMS offered by HC.

- HC supplies three types of BMS for industrial heaters:

- Simple mechanical site operated control panel. It does not require complex cabling, and expensive components, and easy to operate.

- Control system with microprocessors. Control system with microprocessor provides additional digital control features and enable send and receive signals from remote control panel.

- Third type is BMS with PLC and additional digital control and operating functions. BMS enables to connect unit with SCADA or main control system of facility. BMS with PLC has a lot of advantages over conventional BMS, but requires more cables, more electric protection, and expensive components.

As BMS is installed near the burner of heater, it shall be explosion proof and SIL-rated. HC Petroleum Equipment provides water bath heaters and other industrial indirect fired heaters with comprehensive and reliable BMS, meeting project requirements and client’s expectations both in price and quality.

As a leading provider of oilfield water jacket heaters, we are committed to delivering exceptional solutions for you.Our team possesses extensive experience and expertise, allowing us to provide customized solutions tailored to your needs and ensure your requirements are met.

If you are looking for an oilfield heating treater, please contact us for the latest quotation. Alternatively, send your inquiry to sales@hcpetroleum.hk . We will reply to you within 24 hours.

- Application

- Heating of well fluids coming from choke manifold to prevent freezing/waxing of crude.

- Heating of raw natural gas before turbines.

- Heating of sulfur gas in sulfur processing facilities.

- Heating of chemicals to maintain proper temperature meeting process requirements.

- Features

- Sour medium

- Heavy fouling medium

- Salty medium

- Specified kind of burner and fuel as per client requirements

- Specified kind of control

- Remote automation and control

- Skid-mounted or trailer-mounted

- Design Code & Standards

- CE

- PED

- UL, Exp

- NACE MR0175

- API SPEC 12K

- API 6A, API 6D

- ASME Section VII, DIV 1

- ANSI B31.3 Class M (H2S)