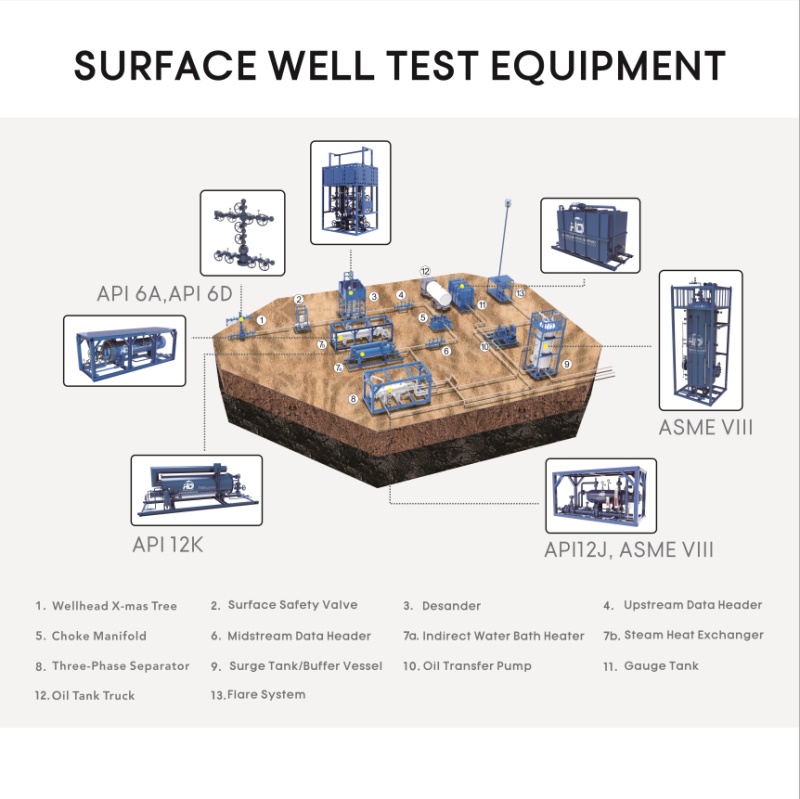

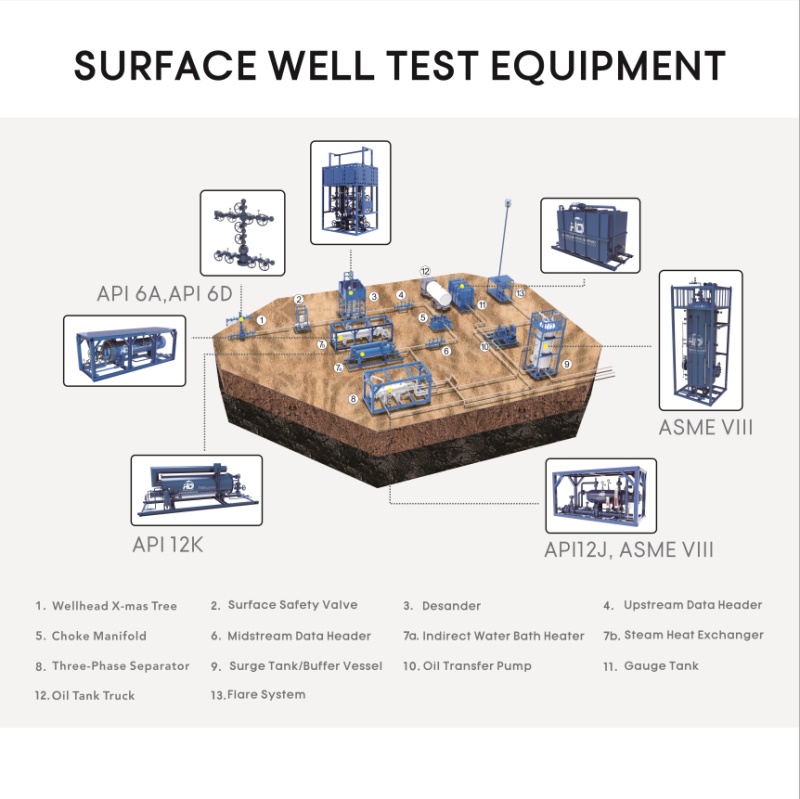

Our well testing equipment is designed and manufactured in accordance with international standards. All materials meet the quality standards of the United States, Europe, Korea, and Russia, such as CE / PED, ASME, API, GOST and other standards. Contact us for the Latest stock and quotes.

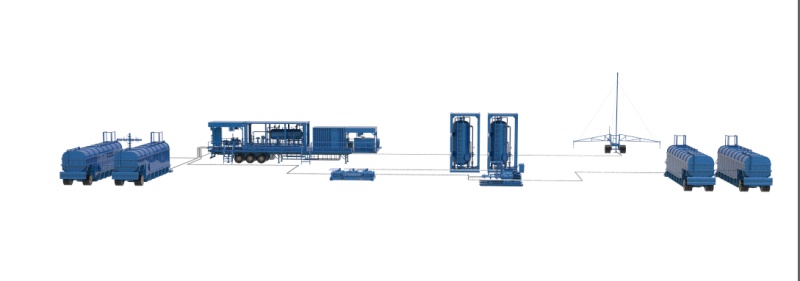

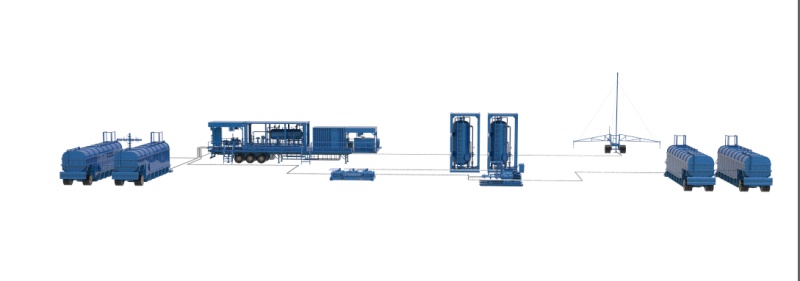

Trailer-mounted well test equipment

Trailer-mounted well test equipment can be fit in special-purpose trailers, which enable clients to conduct fast and effective well testing and fast mobilization of the equipment. Also, known as Dual Trailer system which equipped with manifold, separator, surge tank in one trailer, and data collection and control point on second trailer. Trailer structure and number depends the client’s requirements or can be proposed by our company.

Atmospheric gauge tank

Atmospheric gauge tankis used for the storage of produced fluids, calibration of the metering instruments on the test separator and helps oil effectively drive to the burner boom.

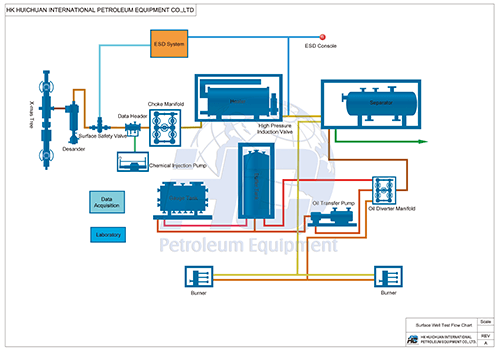

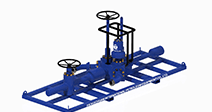

Choke Manifold

Choke Manifold is an assembly which consist of high-pressure valves and chokes, used for reducing the pressure from the well head. It is operated by opening and closing an adjustable or fixed choke.

Burner boom

Burner boom is assembly used for the disposal of the produced fluids during the operation. Burner assembly has combustion water injection system for proper burning and operation.

Surface Safety Valve (SSV)

Surface Safety Valve (SSV) is one of the imp ortant safety equipment of the well testing operations with high flow rate and high pressure. Controlled by ESD system, SSV automatically shuts down the flow and prevent injury of personnel and damage of the facility.

Diverter manifoldis

Diverter manifoldis valve assembly, used for diverting the produced oil and gas to the proper process destination. Oil diverter manifold diverts oil to the burner boom or surge tank, while gas diverter manifold diverts to flare stack or burner boom.

Transfer pumps

Transfer pumps used for filling and emptying the tanks and increasing the pressure for burner boom. Pumping unit is equipped with explosion proof electrical motor and control panel. The common type of pump is centrifugal, while gear and screw types are also available depending on the operation conditions.

Test Separator

Test separator is an important equipment for well testing, used for separating well head fluid to three phases, oil, gas, water. Internal components and sophisticated control & measure parts of separator skid ensures proper separation process and getting samples of the fluid. Data collected from separator is important to evaluate properties of the reservoir / well fluid.

Desander

Desander is designed for separation and filtering the sands and solids of the fluids coming from the wellhead to prevent damage of equipment in the line next and prepare fluid for further processing, such as heating and separation. Structure of desander, filtering elements and accumulator are designed depending on the operating conditions.

Surge tank

Surge tank is used for storage of produced fluids; further separation, where longer retention time is required; and metering to ensure effective and safe well test and production operations. Surge tank are equipped with valve and instrumentation, including sight glasses and calibration strips.

Data Header

Data Header is high pressure assembly for collection of data wellbore production parameters, such as pressure, temperature, sand condition. Also, Data Headers used for chemical injection and safety purposes. Data Header usually installed before and after Choke Manifold.

Surface Test Tree (STT)

Surface Test Tree (STT), also known as Flowhead, is designed to control and direct the flow of well head liquid. SST is installed on the surface, consists of gate valves, flow and kill valves, lifting sub and swivel. Dimensions and structure may vary depending on the operation conditions.

Onshore crude oil burner

Onshore crude oil burner is special mechanical equipment designed to safely dispose crude oil by combusting it during surface well testing. Burner skid consists of oil line, water-sparing line, air line and other parts for safe and effective crude oil disposal.

Water Bath Heater

Water bath heater is designed to heat the media (oil, gas and other substances) of flow by indirect heating. Water bath heaters are used in surface well testing and early production facilities to provide safe and effective heating for gaseous and liquid hydrocarbons facilitating hydrocarbon processing and transport.

Steam Heat Exchanger

Steam heat exchanger is a special item of surface well testing, which is designed to safely and effectively heat the well stream. Steam heat exchanger can be equipped with choke valve to reduce flow pressure before media enter downstream 3-phase separator. Steam for steam heat exchanger is supplied by a boiler which is usually installed in safe area, providing additional safety feature

Flare stack

In surface well testing, gas flaring is conducted by 40 ft. or 60 ft. flare stacks, which can be mobile, installed on a trailer. Trailer-mounted gas flares are very convenient to be mobilized, installed and operated. Gas flaring systems consists of multiple pilot gas lines, automatic ignition system, flare tube, flare tip and other components necessary for safe and reliable operation.

Cyclonic Desanders

Cyclonic wellhead desander are designed to remove sands and solids present in well fluids. Cyclonic wellhead desanders are the essential equipment for sand removal and downstream equipment. Cyclonic desander is the first sand management equipment on the surface where gases and fluids comes to contact with surface equipment after wellhead Christmas trees.

Lab and Office Cabin

The laboratory and office containers are the special designed and fabricated containers used both in offshore and onshore to provide necessary utilities and operating space for the personnel. Lab cabin may contain basic and important equipment necessary for surface well testing. Lab cabin also services as office cabin providing means and space for personnel to fully operate.

SWT Trailers

Specialized and custom-made surface well test trailers are commonly used during onshore oilfield operation, where mobilization and access to utilities are very difficult. SWT trailer may consists of several process and utility equipment, modified and constructed considering to the requirements of operation, safety and transport.

Storage tanks

Storage tanks are specialized mechanical items of surface well testing or production facility allowing the operators to effectively store and dispose hydrocarbon and non-HC liquids. Storage tanks are usually portable with gauges, valves and piping. Portable tanks shall be safe and convenient for mobilization. Tanks may contain heating coils in case of low ambient temperature and as the means of preventing fouling oil hydrocarbons.