Production Separator Basic Specification Data

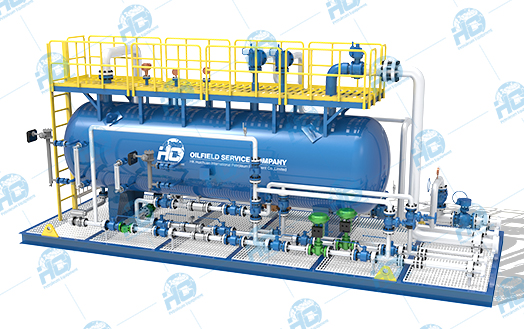

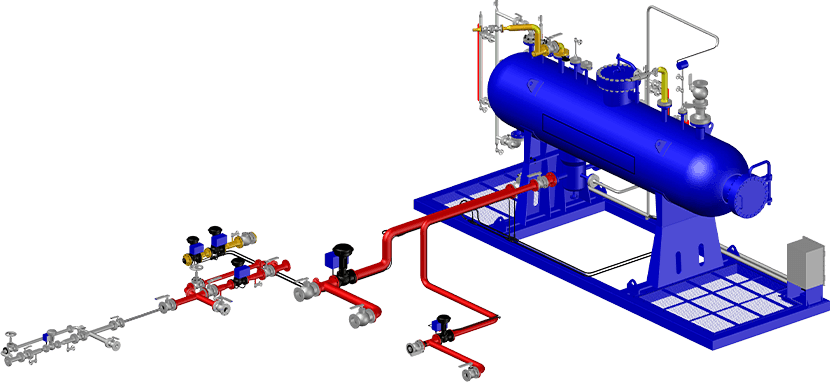

Separator can be designed as per client’s operation conditions depending on flowrate, temperature, pressure, working medium and other operation data. Most of the production separators are designed for comparatively big capacity of 6000-20000 BOPD.

Horizontal Separator / Vertical Separator

According to the installation mode, the separator can be divided into horizontal/vertical installation, or indoor/outdoor installation.

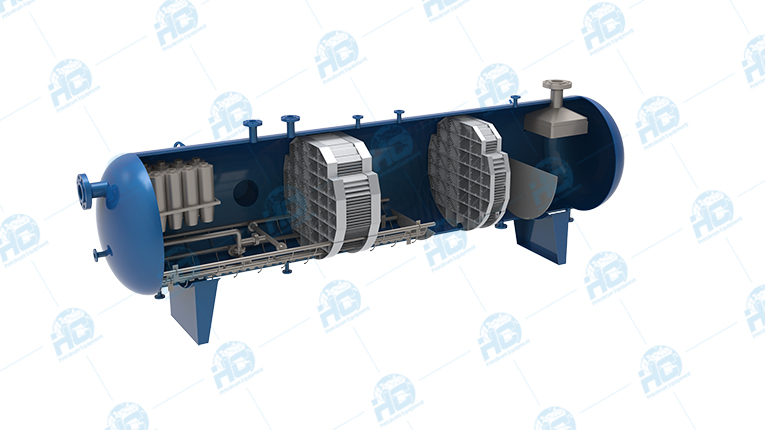

The horizontal separator is built horizontally, in other words, as the vessel shell axis parallel to the ground. It is usually used for large liquid/gas ratio fluid treatment or liquid/liquid separation. Compared with vertical separators, there are longer horizontal sections for liquid flowing and shorter vertical sections for gravity separation of liquids with different densities. The horizontal separator requires a relatively large horizontal installation space, and its application is generally not affected by the field wind.

Horizontal separator can be used for test separator, production separator, two-phase separator, three-phase separator and special application separator.

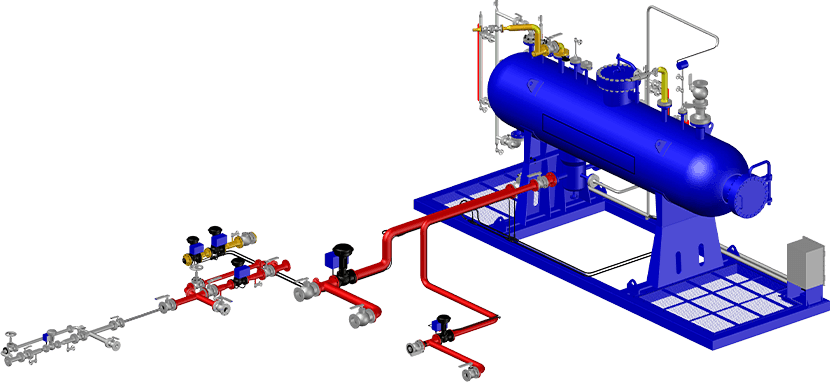

The vertical separator is built vertically, which means the vessel shell axis is perpendicular to the ground. It is usually used for large gas/liquid ratio fluid treatment. Compared with horizontal separators, there are larger cross-sectional area for gas flowing and longer vertical sections for gravity separation of liquids from the gas. The vertical separator requires a relatively small horizontal installation space, but for very high or slender separator the field wind shall be considered.

Vertical separator can be used for test separator, production separator, two-phase separator, three-phase separator and special application separator.

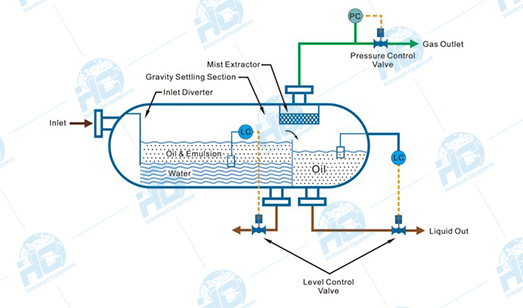

Process Principle and Working Mechanism of Separators

In oilfield production, the extracted fluid usually consists of a mixture of crude oil, natural gas, and water. Without effective separation, it is impossible to meet the requirements for storage, transportation, and further processing. The separator is therefore a key piece of equipment designed for this purpose.

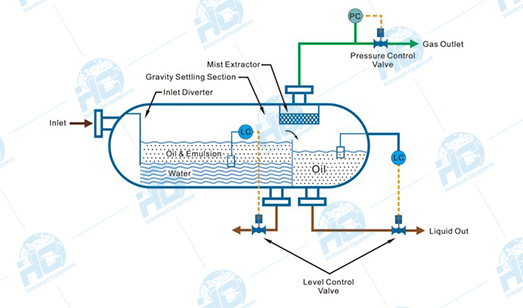

The working principle of the separator is mainly based on gravity settling, fluid dynamics, and interface control. When the multiphase fluid enters the separator, its velocity decreases sharply. The gas, being the lightest component, separates first and flows to the gas outlet. The liquid phase is then divided by gravity: water, with a higher density, settles at the bottom, while oil forms a layer above the water, creating a stable oil-water interface.

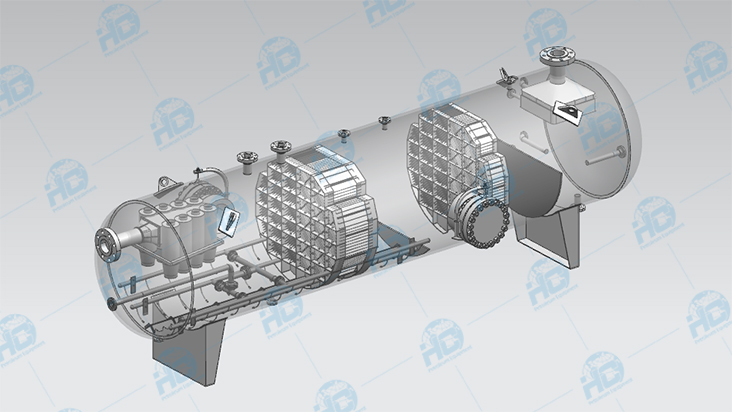

In operation, the separator is typically equipped with an inlet distributor, gas separation section, liquid settling section, baffles or coalescing devices, and an interface control system. The inlet distributor reduces fluid impact and ensures uniform distribution. The gas separation section, often fitted with a demister, removes liquid droplets from the gas. The liquid settling section provides sufficient residence time for natural stratification of oil and water. Automated level and interface control systems maintain stable three-phase discharge.

Ultimately, the separator enables efficient separation of gas, oil, and water , ensuring the continuity and safety of oil and gas processing operations.